Every time we toss out an old T-shirt or discard a disposable medical patch, we’re contributing to a rapidly escalating environmental crisis. The world produces over 92 million tons of textile waste annually, much of it made from synthetic materials that can linger for centuries. Add to that the surge in wearable electronics — smartwatches, fitness trackers, sensor-laden garments — and the problem becomes twofold. These e-textiles don’t just include fabric, but also metal wires, plastic substrates, adhesives, and circuits that are nearly impossible to recycle. As electronics become more intimate, wearable, and disposable, the question becomes urgent: how do we design them to disappear when they’re no longer needed?

A research team at Seoul National University has taken a significant step toward answering that question. Led by Professor Seung-Kyun Kang and Dr. Jae-Young Bae, the team has developed a fully biodegradable, high-performance conductive fiber that can be seamlessly integrated into wearable electronics — and naturally decompose after use. Unlike conventional e-textiles that persist in landfills, this new fiber system maintains performance during use but vanishes in enzyme-rich or soil environments, leaving no harmful residues behind.

The team’s innovation lies in combining tungsten microparticles with a biodegradable polymer known as poly(butylene adipate-co-terephthalate) (PBAT) to form a conductive fiber. This core is coated with a flexible, water-resistant polyanhydride (PBTPA) layer that enhances mechanical stability without compromising biodegradability. The fiber achieves an impressive electrical conductivity of approximately 2,500 S/m, stretches up to 38% without failure, and endures over 20 laundry cycles and 5,000 bending events — performance metrics comparable to or better than many existing e-textile solutions.

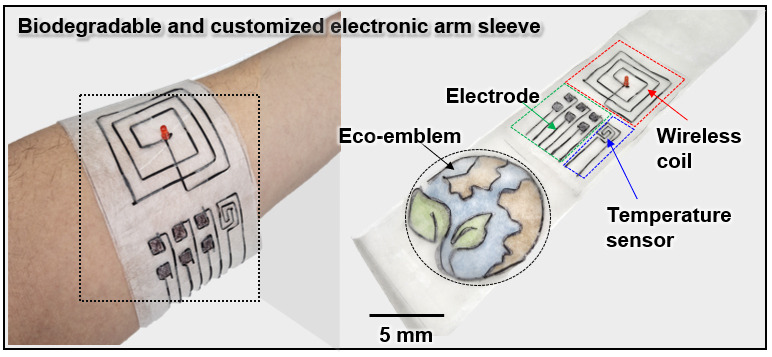

Crucially, the fiber is compatible with dry-jet wet-spinning, a scalable process that enabled the team to produce lengths exceeding 10 meters in a continuous run. To validate its real-world applicability, the fiber was integrated into a wearable smart sleeve featuring a temperature sensor, electromyography (EMG) electrodes, and a wireless power coil. The device operated reliably under dynamic movement and environmental stress. After use, the entire system — including the embroidered eco-emblem — began to decompose when exposed to soil or enzymes, fully disintegrating within a few months.

“This is more than just a new material — it’s a platform for sustainable electronics,” said Professor Kang. “We’ve shown that you can have high-functioning wearable devices that don’t become e-waste after their useful life ends.”

Dr. Bae added, “The ability to design electronics that match the lifecycle of the application — and then gracefully disappear — opens up new possibilities in medical patches, smart uniforms, environmental sensors, and beyond. We’re especially excited about the potential for use in disposable healthcare systems that don’t contribute to long-term pollution.”

The research represents a rare confluence of biodegradability, mechanical performance, and mass-manufacturability. Looking ahead, the team aims to expand the platform to incorporate fiber-based memory and logic components, moving toward fully integrated, transient electronic systems. They are also exploring “triggerable” degradation mechanisms that respond to light, heat, or pH — enabling programmable lifespans for future devices.

The study was published in npj Flexible Electronics.

[Refence Materials]

- Resources : Kim, YW., Kim, KS., Park, JH. et al. Fully biodegradable and mass-producible conductive fiber based on tungsten–poly(butylene adipate-co-terephthalate) composite. npj Flex Electron 9, 62 (2025).

- Video Demonstration : https://youtu.be/lwBe_4SVCF0?si=DzMqQl_YglKY8dIa

- Broadcast Video (YTN Science) : https://www.youtube.com/watch?v=DwbUwIWpfq4

- DOI : https://doi.org/10.1038/s41528-025-00448-x

[Contact Information]

Prof. Seung-Kyun Kang (kskg7227@snu.ac.kr) / Dr. Jae-Young Bae (jy.bae@snu.ac.kr)